Conex Banninger™

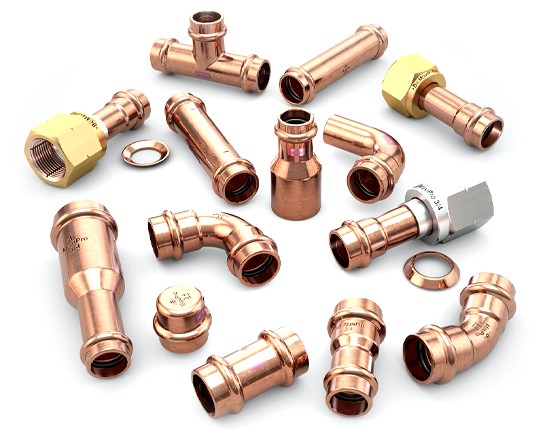

>B< MaxiPro Press Fittings

An innovative pipe jointing system which is quick and simple to install whilst providing a reliable, secure and permanent joint. Designed specifically for air conditioning and refrigeration applications.

Benefiting from over 100 years’ experience in fittings manufacture and over two decades experience in press system design, >B< MaxiPro revolutionises pipe jointing in air conditioning and refrigeration applications. Compared with traditional techniques it significantly improves productivity through greatly reduced installation time and enhanced working flexibility.

>B< MaxiPro can be used with hard, half-hard or annealed copper tube conforming to EN 12735-1 or ASTM-B280, in both air conditioning and refrigeration applications. Passionate about excellence, Conex Bänninger is a byword for quality in the domestic, commercial, industrial, shipbuilding, air conditioning and refrigeration markets worldwide.

Conex Bänninger is an ISO 9001 company, which assures their customers of consistency in the quality of their services and products.

We invite you to become part of the Press Revolution!

>B< MaxiPro Press Fittings

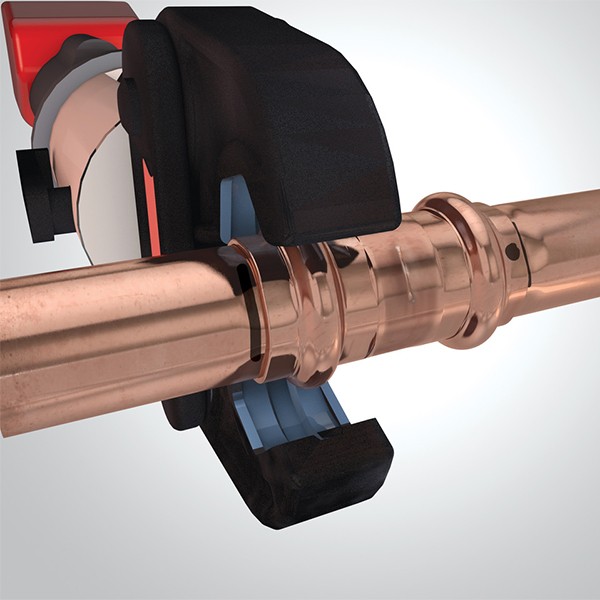

No brazing, no hot works. Just compression.

>B< MaxiPro is an innovative press system, which is quick and simple to use, providing a secure and permanent joint. Compared with traditional techniques it significantly improves productivity through greatly reduced installation time and enhanced working flexibility.

>B< MaxiPro is revolutionising pipe jointing in air-conditioning and refrigeration applications. Use of a press-fit fitting means no need to purge the system with nitrogen as its assembled, no risk of fire so no need for hot works permits. The range is suitable for use on both coiled and straight copper tube from 1/4” through to 1.3/8” with an operating pressure of up to 48bar.

Online training is provided free of charge and, once completed, results in a 10-year warranty for all installations.

- >B< MaxiPro benefits from a 3-point press – one each side of the bead, and one press compressing the O-ring. This provides a permanent and secure joint.

- Lead-in edge design aids installation and helps protect the O-ring from damage or displacement.

- >B< MaxiPro fittings for air-conditioning and refrigeration applications are identified with pink marks on the fitting.

- >B< MaxiPro system is quick, simple and easy to use.

- Backed by experienced technical support and customer service teams.

- Reliable, repeatable, permanent, tamper-proof connections every time.

- Reduced installation time, lower overall cost.

- Intrinsically safe – no fire hazard, dangerous materials or fumes.

- No unintended damage as a result of heat.

- UL certified and extensively tested.

- >B< MaxiPro is covered by a 5-year product Guarantee.10 year warranty available on completion of FREE online training. Please refer to the >B< MaxiPro Guarantee document. For more information on training please contact your local branch today.

Click to download or view our >B< Maxi Pro literature. For further information, or to order, please click through to the product page or contact your local branch.

Join the Press Revolution - 10-year warranty available (on completion of FREE online training)

>B<MaxiPro Press Tooling

Rothenberger Romax Compact Kit

Manufactured by Rothenberger the tooling comes in 2 sizes. The Compact TT tool is suitable for fittings up to 1.1/8” in size, and the new ROMAX 4000 tool can press fittings up to 1.3/8. Our tool kits come with the tool, charger and 2 batteries plus jaws (depending which kit you choose).

The Compact TT electro-hydraulic radial press machine, which weighs only 2.5kg, uses turbo pressure for pressing metal fittings up to Ø 1.3/8" mm in only 3 seconds. Enormous power on just 34 cm length thanks to its two-cylinder construction.

The perfectly distributed weight facilitates working in continuous use. The larger ROMAX 4000 is an electro-hydraulic, battery-powered press machine for system up to Ø 1.3/8" with a force of 32-34 kN. Improved battery technology allows an increase in pressings per single charge. The low weight of only 3.6 kg and a balanced weight distribution reduces fatigue and enables operating in a more ergonomic and effort-saving way even during continuous use. CFT technology guarantees a constant thrust during each press cycle. The increased service interval of 40,000 pressings/ 2 years reduces downtime and increases productivity.

Both tools are designed to give strength, durability and the ability to operate in tight areas.

- Quick Change Jaws - Simple to change, secure locking system.

- Reducing length to 34cm. The smallest machine on the market.

- Ergonomic - Single-handed operation, soft-grip handle.

- Perfect Balance - Centre of gravity in the middle of the machine reduces fatigue when in use.

- Shoulder Strap Hook - Can be hung from the shoulder using the operational hanging strap to reduce user fatigue.

- High performance - 18v Li-ion battery platform, 2.0Ah or 4.0Ah available.

- Battery Status Indicator - Gives visual warning of battery charge level (will not press if insufficient charge).

- Emergency Stop - Instant interruption of pressing cycle and piston withdraws to start position.

- FAST - 3-second pressing cycle.

- eTool - Built-in electronic tagging can monitor machine data via a downloadable app.

- CFT - Constant Force Technology guarantees constant pressing force of 19kN throughout the pressing cycle.

- Service Indicator (y Ear) - Gives visual service warning of 40,000 press cycles.

- LED Light - Illuminates workspace when in use.

- Rotation - Head can be rotated through 270 degrees, ideal for use in confined spaces.

Click to download or view our Press Fittings Tools literature. For further information, or to order, please click through to the product page or contact your local branch.

Join the Press Revolution - Fast working by pressing in under 5 seconds!